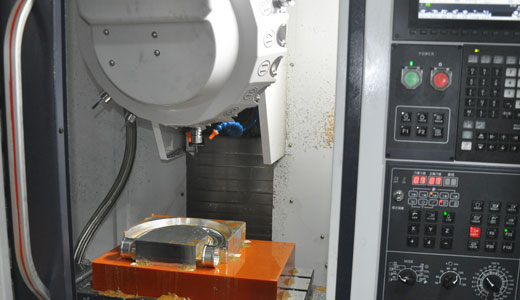

JINGXIN is a complete CNC machine shop capable of machining custom parts to customer specifications (conventional and 5 axis machining). The most common machined stainless steels in our CNC machine shop are the austenitic types, such as grades 304 and 316. These are characterized by their high work hardening rates and poor chip breaking properties during machining.

Custom stainless steel parts, CNC machined stainless steel components

JINXIN is a precision Custom stainless steel parts manufacturer in China, we supply custom CNC machined stainless steel parts service including Precision CNC milling 304 & 316 stainless steel parts and CNC Precision Turned stainless steel Components, For example, the custom stainless steel parts are often used for containers, handles, marine parts, engine parts, cooking utensils, medical devices, hospital instruments, lab equipment, pressure tanks, fasteners, automotive parts, pressure tanks, fasteners and architectural parts.

JIngxin has over 15 years of experience in custom CNC machining services, Located in Dongguan City China. JINGXIN’s Professional team adopt reasonable manufacturing solution and workmanship to supply high-quality one-stop custom CNC machined stainless steel parts.

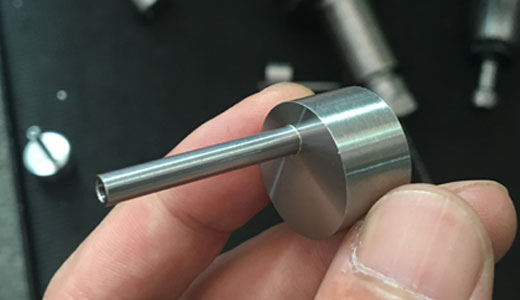

JINGXIN focus on custom Non-standard CNC precision milling parts such as Fittings, valves, hydraulic components, electric motor parts, transmission and pump parts, sprocket wheels, wear parts on packing machines and electronic and medicinal pieces.

– Austenitic steels such as 304 surgical stainless cannot be hardened by heat treatment.

– Ferritic steels such as 430 contain iron and are less ductile than austenitic steel and cannot be treated by heat.

– Martensitic steels such as 410 are low carbon and may be tempered and hardened but are brittle.

Advantages Of CNC Machining

CNC machining is great to meet a range of your product development needs. Here are some of the benefits of precision machining:

At JINGXIN CNC milling company, we supply high precision custom stainless steel parts with world brand CNC machines, CNC turning and milling machine center. it allows us to deliver high-quality and on-demand precision turned components and CNC milled components, Typical tolerance from +/-0.002mm to +/-0.01mm for metal parts. Please our whole factory show for more details about precision CNC milling equipment.

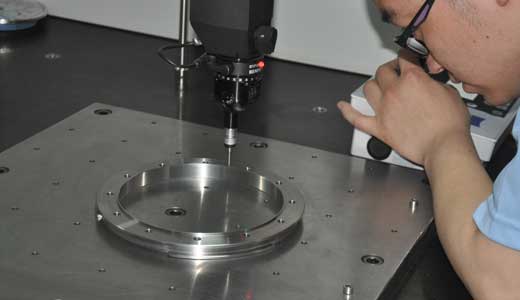

100% inspection before delivery. Every single size would be checked by the related testing instrument. CMM, H.gauge, M. Microscope.etc. Please see our Quality assurance for more details

Our skilled Engineer optimizes the tooling path and proposes a best CNC machining process solution according to the design and customer’s request. JINGXIN served worldwide customer for the following parts and so far it is well done: Precision machined 304/316 stainless steel parts, locknut shaft, precision turning aluminum electric motor parts, Precision CNC milling new energy device components, Precision turned aluminum components for electronic and medicinal products.

For every single precision CNC machined parts, Our team including R&D and production departments will work together to finalize the manufacturing workmanship process. Three key factors to ensure the quality: 1. Best manufacturing solution & workmanship; 2. optimized tooling path; 3. PQC during the whole production.so that JINGXIN can ensure the quality parts what is you want from a Precision machined parts supplier in China

We can make various Surface treatment and finish as customer requirement for Precision Machining metal or plastic parts. Including Anodizing, Black oxide, electroplating,.etc, please see Surface treatment and finish for more details

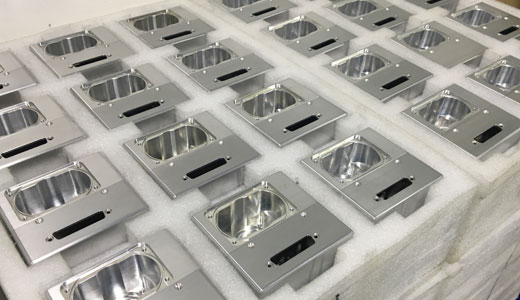

1. 1-2 weeks Fast Lead time and 3-5 days Rush services,

2. On time delivery by worldwide express UPS, DHL, FedEx, TNT.etc

3. Proper safe packing: Enhanced Carton and wooden case

For example: if the order quantity of Precision turned components are below 5000 pcs, then the lead time is 2 weeks, shipping time 2-3 workings days, so you will get the parts less three weeks. also, we supply rush service if you need urgently.

As a branch of J AND R METALWORK, Hunan Jiashan Tech has been a trusted name in the manufacturing industry since 2005. e specialize in China CNC machining services as our core offering, backed by nearly 20 years of technical expertise and industry experience. Our goal is to be a leading supplier in the global hardware sector, with active memberships in both the Hardware Industrial Association and Green Energy Industry Association—testaments to our commitment to quality and sustainability.

Copyright © 2025 Siluzan All Rights Reserved.