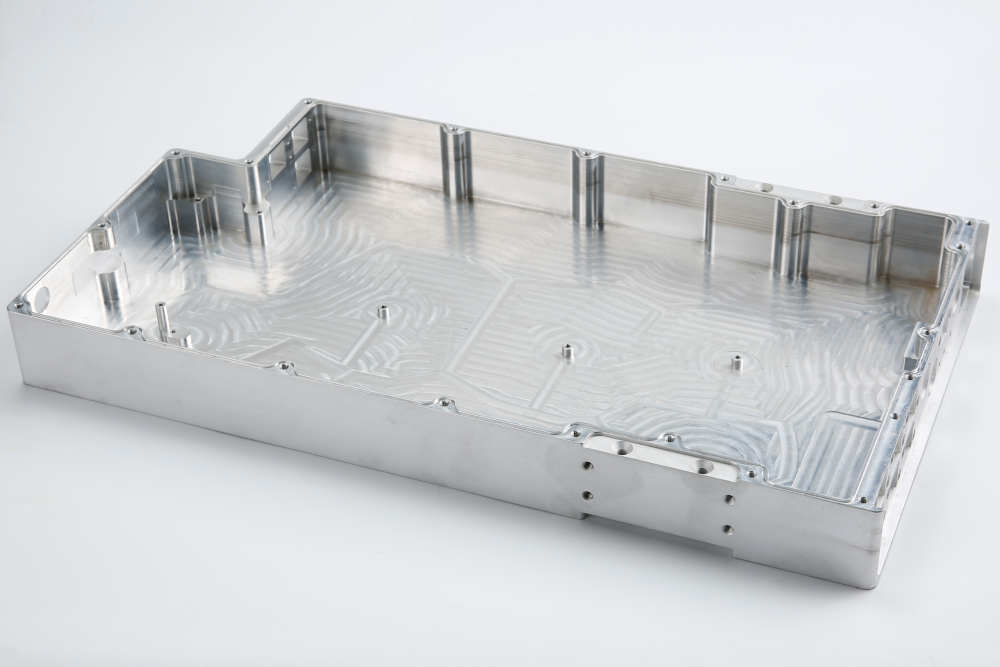

Let us bring your product design or idea to life with our top-tier CNC milling services. We offer CNC milling services for pretty much any design and for a broad range of metals and plastics.

Using our state-of-the-art multi-axis milling machines, our team of highly qualified engineers and machinists get your products done right the first time. We also have a dedicated quality control team that tests and ensures that all CNC machined parts meet our customers’ requirements and the required standards and regulations.

China CNC milling services complement our many other manufacturing and finishing capabilities, providing you with an all-encompassing and satisfactory solution for your product development project.

CNC milling is a form of manufacturing that involves removing material from a workpiece to create a finished shape. The CNC milling process starts with you creating a 3D CAD model of your desired part geometry before converting it to a computer program (G-code) using CAM software. This computer program then automates the operation of the cutting tool to create your desired parts.

CNC milling is similar to CNC turning: both processes rely on computer instructions to create parts. However, they differ in their modes of operation. The workpiece is held in place in CNC milling as the cutting tool rotates around it. In contrast, CNC turning involves holding the cutting tool in place while the workpiece rotates around it.

Nevertheless, CNC milling and turning processes have several advantages and are ideal for different manufacturing needs.

CNC milling is ideal for making angled shapes, channels, slots, holes, curves, chamfers, among other complex geometries and features. It also offers a short lead time as parts can be created within minutes, whereas conventional machining processes (like injection molding) might take days (sometimes weeks) to complete.

CNC milling machines are also compatible with a broad range of materials, including metals, plastics, and composites. This is one of the primary advantages of CNC machines over additive manufacturing processes like 3D printing, which can only create plastic and a few metal parts.

You should also opt for CNC milling if you want to create parts with excellent surface finishes, as this subtractive manufacturing process offers a broad range of surface finish options, including painting, chroming, and anodizing.

• Machine Brands: Brother, Fanuc, and others (21 Machine Sets in Total)

• Part Dimensions Up to 1000*600mm

• Software: Solidworks, MasterCAM, AutoCAD, Esprit Software

• 3- Axis, 4-Axis, 5-Axis CNC Milling

• Multi-Axis Aircraft Machining, Precision Medical Components, and Complex Shapes for Every Industry

• ISO 9001:2015 certified Quality Management System and ISO 14001:2015 certified Environmental Management System.

As a branch of J AND R METALWORK, Hunan Jiashan Tech has been a trusted name in the manufacturing industry since 2005. e specialize in China CNC machining services as our core offering, backed by nearly 20 years of technical expertise and industry experience. Our goal is to be a leading supplier in the global hardware sector, with active memberships in both the Hardware Industrial Association and Green Energy Industry Association—testaments to our commitment to quality and sustainability.

Copyright © 2025 Siluzan All Rights Reserved.